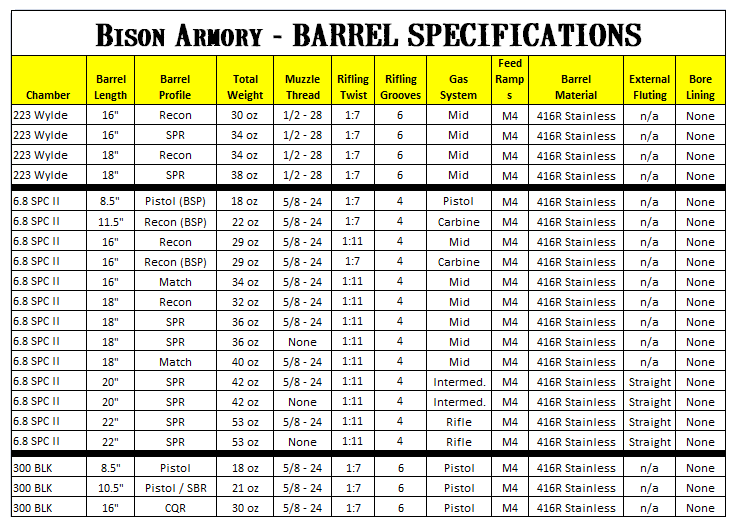

Barrel Specs

General

Bison Armory 6.8 SPC AR-15 rifle barrels are made by E.R. Shaw and White Oak Armament. Shaw makes our standard barrels while White Oak uses Shilen blanks to make our match grade barrels. Our barrels are fully capable of MOA accuracy when fed quality ammunition, and our profile supports Ops Inc 12th Model silencers, as well as silencers from Surefire, AAC, Gemtech, and YHM. Our barrels are made with the following specifications:

SPC II Chamber

The SPC II designation refers to the updated chamber specification for the 6.8 SPC. The freebore in the chamber was increased to 0.100" which reduced the chamber pressure of the 6.8 SPC and allowed higher power ammunition to be used safely.

With the new chamber spec, the 6.8 SPC is able to realize its full potential as a hunting/combat round. Other updated chamber specs exist, including the 6.8 x 43mm and Noveske 6.8mm SPC MOD 1, which are similar to the SPC II.

Rifling: Grooves and Twist Rate

The 6.8 SPC is available from different manufacturers with twist rates from 1:9.5" to 1:12". In the past it seemed reasonable that the lower twist rates of 1:11" and 1:12" would yield the highest muzzle velocities for a given cartridge load as lower rates of twist apply less impedance on the bullet as it travels down the bore. The difference in velocity between 1:11 all the way down to 1:7 however is imperceptible if it is even there at all. At Bison Armory, we have settled on 1:10" twist rates for 6.8 SPC barrels 18" and longer, and either 1:7" or 1:11" twist for 16" barrels. Shot side by side in a 16" barrel, we cannot tell the difference in accuracy or muzzle velocity between a 1:7" twist and a 1:11" twist barrel.

For stabilizing heavier bullets, 130 grain and up, 1:11" or faster twist rates work well. However, when loading for subsonic applications with 150 grain or heavier bullets a faster twist rate is desirable for projectile stabilization, as the longer bullets must have a higher rate of spin to achieve stable flight. Bison Subsonic Platform (BSP) barrels have a 1:7" twist rate that can stabilize a 200 grain projectile moving at 1050 fps.

The 1:7" twist rate also works with ALL FACTORY 6.8 AMMO: Twist rate has very little effect on performance of supersonic ammo. Until the twist rate is faster than around 1:4", there is virtually no increase in pressure and no loss in muzzle velocity compared with a 1:11" twist barrels. Our own range testing has shown accuracy between our 16" barrels with 1:11" twist and 1:7" twist is identical as well. Nothing is lost in going to 1:7" twist in 16" and shorter barrels.

Barrels are available from different manufacturers with 3, 4, 5, and 6 grooves, with various land/groove geometry. Bison Armory uses the current "standard" spec: 4-groove, 1:11" twist.

Gas System

The gas system is the part of the rifle that cycles the action. For either direct impingement (DI) or Gas Piston Unit (GPU) rifles, the location of the gas port on the rifle barrel relative to the barrel chamber is referred to the gas system length. Gas system length and the diameter of the gas port must be set correctly to ensure reliable cycling of the rifle action. Action cycling is all about gas system timing, and such factors as peak pressure, dwell time, bore diameter, bolt carrier and buffer mass, and others each play a roll in determining the timing of the system.

For reliable action cycling, the shorter the barrel, the shorter the gas system must be. Obviously the gas system cannot be longer than the barrel itself. AR15 gas systems are available in the following standard lengths:

Pistol: Used for the shortest barrels such as very short SBR and AR-15 pistol applications.

Carbine: Used for 16" and shorter barrels.

Mid: The most common gas length. This has become the "standard" gas length for 16" and 18" 6.8 SPC barrels. Sometimes found on 20" barrels.

Intermediate: This is in between mid and rifle length. This gas length is used on some of our 20" barrels in order to ensure proper cycling with all ammunition, especially varmint loads using light bullets.

Rifle: Used on 20" and longer barrels for the 6.8 SPC. This gas length can exhibit short stroking when used with light bullets (85 and 90 grain) in conjunction with very fast powders. Cycling is fine with 110 grain and heavier bullets.

Profiles

There are very many barrel profiles available in the market today. At Bison Armory, our 6.8 SPC BR-15 barrels come in two varieties: Recon and SPR.

Recon Profile: Our Recon profile is the lighter of our two profiles. The profile is 0.75" diameter under the hand guard and at the journal at the gas port. The diameter steps down to 0.70" after the gas block journal. Near the muzzle, the diameter steps up to 0.75" and then back down to 0.72" in order to accommodate the collar for the Ops Inc 12th Model silencer.

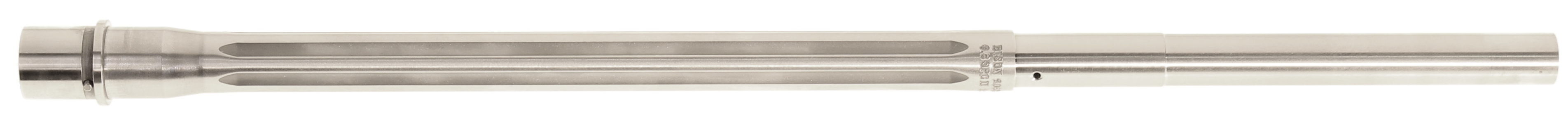

Pictured Above: 18" Stainless RECON Profile Barrel

SPR Profile: The SPR profile is a 6.8 SPC copy of that used on the SPR Mk12 Mod 0/1 rifle. The profile is similar to the Recon except that it is 0.84" under the handguard and never steps below 0.73" after the gas block journal. The 6.8 SPC does not cycle well in an 18" barrel with rifle length gas, so this profile has a dummy gas block journal at the rifle position in order that it can be used in SPR Mk12 Mod 0/1 clone rifles.

Pictured Above: 18" Stainless SPR Profile Barrel

Pictured Above: 20" Fluted Stainless SPR Profile Barrel with Target Crown Muzzle

Pictured Below: 20" Fluting detail

Materials

Our barrels are all made from 416 Stainless Steel. We chose this material as our standard because it is ideal in terms of cost and performance. Stainless steel barrels are typically considered to be the most accurate and are optimum in terms of corrosion resistance.

Finishes

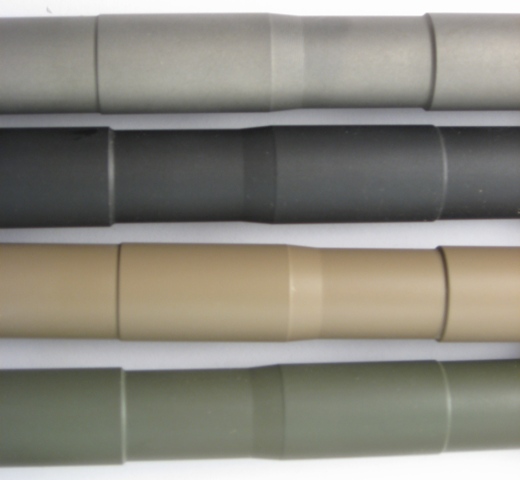

Below (from top down): Bead Blast, Black, Flat Dark Earth, OD Green.

Bison Armory barrels are available in one of three types of finish:

Bare Stainless

The bare stainless finish is our simplest finish and is both inexpensive and nice looking. Match rifles often come with stainless barrels because the finish isn't important as it can be for hunting or combat purposes.

Bead Blasted

Bead blasting takes the shiny stainless finish of the barrels down to a dull grey. This finish is very attractive, and is desirable for hunting as the surface is no longer reflective.

Coated

We use Cerakote as our standard barrel coating. Cerakote is available on Bison Armory barrels in Flat Black, and Magpul versions of OD Green, Foliage Green, and Flat Dark Earth. Only flat black is a standard finish and kept in stock. The other colors are custom ordered and require an additional three weeks to complete the order.

Cerakote has proven to be a very tough finish. The barrels are first bead blasted, then de-greased, coated, and finally baked.

Gas Block Dimples and Pinned Gas Blocks

All of our barrels come standard with a single dimple opposite the gas block port. This ensures that a low profile gas block that uses set screws will be perfectly aligned with the gas port, and also makes it nearly impossible for the gas block to be moved out of place.

We also offer gas block pinning for an extra charge, which ensures that a low profile gas block cannot be unintentionally moved out of place. We've never had a customer report that one of our low profile gas block installations has failed. But for guaranteed performance, especially if the weapon is for police, military or any serious tactical application, then you can't go wrong with a pinned gas block.

The following image shows the gas block alignment dimple we put in all of our barrels (top) and a pinned low profile gas block (bottom).